Post recommended by Eng. Mohamed Fathy, the author of this post and special thanks for his efforts in enrichment our blog

Function Of Unit

Converts low octane number naphtha into high octane gasoline product on continuous basis as basis as the catalyst is continuously regenerated in the CCR section.

Involved Reactions

Dehydrogenation of Naphthenes

Isomerisation of Naphthenes and Paraffins

Dehydrocyclization of Paraffins

Hydrocracking

Demethylation

Dealkylation of Aromatics

Platforming Catalyst

Platforming catalyst is Bifunctional type which has:

• Acidfunction

– Responsible for Naphthenes Isomerisation and provided by Chloride Injection

• Metalfunction

– Responsible for Dehydrogenation and Dedydrocyclization provided by the metalsites

Platforming Reactions

Unit Feed Stocks

Hydrotreated heavy naphtha having the following specs.:

Total Sulfur : <0.5 wt-ppm

Total Nitrogen: <0.5 wt-ppm

Distillation End Point : 204 °C (max)

Lead: 20 wt-ppb (max)

Arsenic: 1 wt-ppb (max)

Iron: 1 wt-ppm(max)

Copper + Heavy Metals: 25 wt-ppb (max)

Fresh Feed Quality

Feed with high EP (above 204 °C) are difficult to reform and cause high catalyst coking rate.

Sulphur content above 0.5 ppm will cause temporary poisoning for platinum and lower catalyst activity.

Higher nitrogen content (above 0.5 ppm) will cause loss of acid site activity although hydrogen production will increase.

Product Specifications

Plateformer Material Palance

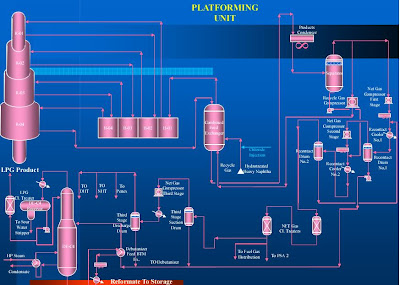

ProcessFlow Diagram

Platforming Section

PLATFORMING UNIT

Plate Exchanger Advantages

Less capital outlay.

lower installation cost (piping, space,…..)

Higher thermal efficiency

Extensive heat exchange area in a single compact unit

Low pressure drop

Range between 0.35-1.5 barg

Low operating cost

less fouling, fewer flanges, accessibility for maintenance through top and bottom manway

PLATE HEAT EXCHANGER SIMPLIFIED OPERATIONS

PLATE HEAT EXCHANGER

DISTRIBUTION HEADER DETAILED DESIGN

Platforming Process Variables

Reactor

Temperature• Reactor Inlet

– Is the major parameter used to meet product quality requirements

• Temperature Difference

– Represents amount of reactions performed in each reactor

Liquid Hourly Space Velocity

LHSV(hr-1) = { volume of feed (/hr) } / { volume of catalyst in Reactors }

**The higher space velocity (lower Residence Time), the lower product RON.

**Increased Reactor Temperatures will offset this effect.

Reactor Pressure

Decreasing reactor pressure will :

•Increase hydrogen and reformate yield

•Decrease temperature requirement to achieve target Octane Number

•Increase catalyst coking rate

Hydrogen/Hydrocarbon Ratio

Increasing Hydrogen/Hydrocarbon Ratio will :

•Increase temperature requirement to achieve target RON

•Decrease catalyst cokingrate

H2/HC Ratio = { RG Purity X Recycle Gas Rate, Kmol/hr } / { Fresh Feed, Kmol/hr }

Reactor

The catalyst flows by gravity out from Reactor bottom to the top of the next reactor. Through catalyst Transfer pipe Catalyst continues to flow through each reactor flow through each reactor until it again reaches the bottom of the last reactor.

This completes the transfer circuit. Catalyst flow between the reactors is through equally-spaced transfer lines designed to ensure uniform catalyst flow through the catalyst bed.

I can see that you are an expert at your field! I am launching a website soon, and your information will be very useful for me.. Thanks for all your help and wishing you all the success in your business.

ReplyDeleteמדביר מקצועי